Hi-Tech Products Die Cutting and Converting

Hi-Tech Products Die Cutting and Converting

Call: (714) 670-2150 ISO 13485:2016 Certified

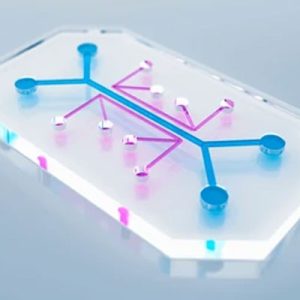

Clean Room Medical Rotary Die Cutting

Hi-Tech has over 30 rotary die cutting presses, 12 in certified cleanrooms. Including 8 state of the art, servo presses with up to 14 stations, capable of handling widths up to 24” wide. Servo presses in certified cleanrooms are capable of island placement with electronic registration and inline heat seal pouching.

Pre-cut shapes of adhesive are laminated to material during the die cutting process, leaving adhesive positioned only in the specified area(s). Adhesive free substrates can also be island placed. Hi-Tech Medical has 8 state-of-the-art servo rotary presses capable of island placement in certified cleanrooms.

Hi-Tech Medical can pre-print any type of pouch material and package die cut parts inline as they are cut, while printing sequential lot numbers.

Hi-Tech Medical has inline Flexo printing on numerous presses in the US and Mexico.

Hi-Tech Medical can laminate a variety of flexible substrates together with heat or PSA, without entrapping air or contaminants and not stretching the substrate.

Pre-printed adhesive materials can be accurately die cut utilizing electronic registration, leaving adhesive positioned only in specified areas. Adhesive free substrates can also be pre-printed and island placed.

Hi-Tech Medical is capable of building one-of-a-kind presses if needed to meet your unique requirements.

Patient Monitoring and Specialty Electrodes

Patient Monitoring and Specialty Electrodes

Medical Device

Medical Device

Attachment

Wound Care /

Wound Care /

Ostomy

Diagnostic

Diagnostic

Components

Drug

Drug

Delivery

A 3M / Solventum Premier Converter has certified expertise, backed by a history of 3M / Solventum quality and innovation.

Hi-Tech Products understands the industry and exceeds expectations. 3M Preferred Converters have certified expertise, backed by a history of 3M quality and innovation. Count on this shared industry knowledge and experience to enable us to provide the highest quality materials and precision die cutting manufacturing. See more.

No substitute for experience

Hi-Tech Product’s die cutting specialists deliver high quality die cutting company services. Founded in 1979 by Jim Ruch, a Mechanical Engineer, Hi-Tech Products is one of the most advanced providers of die cutting services in the USA. Hi-Tech Products is ISO 13485:2016 certified, ISO 9001:2015 certified, and operates multiple locations in the USA and Mexico, to serve our global customers’ converting, assembly, and packaging needs.

Rotary Die Cutting Services Reliablity

Since 1979, Hi-Tech has established a reputation for on-time delivery, quality & consistency. Because of our ongoing level of service, confidentiality, and integrity, the majority of our customers have been with us for over 10 years.

Adhesive Converter California – Hi-Tech Products is based in Buena Park California and performs precision die cutting in certified cleanrooms.

With over 40 years in the business of rotary die cutting services and more than 400 active customers, Hi-Tech Products has developed processes that meet the most demanding requirements & specifications.

Hi-Tech has been involved in the development of a wide range of products for virtually every application. This depth of experience & materials knowledge allows Hi-Tech to often provide critical insights to help clients avoid expensive mistakes.

Die Cut Products Manufacturing

With two facilities in the USA and Mexico, Hi-Tech Products has a wide range of capabilities and provides every type of die cutting service.

Our converting services include precision die cutting, laminating, slitting, printing, RF welding, and laser can be done in certified cleanrooms. Labor intense converting, packaging, and assembly are performed in Mexico at off-shore labor rates.

Hi-Tech Products is also a CTPAT Partner making importing from our factory in Mexico fast, efficient, and reliable.