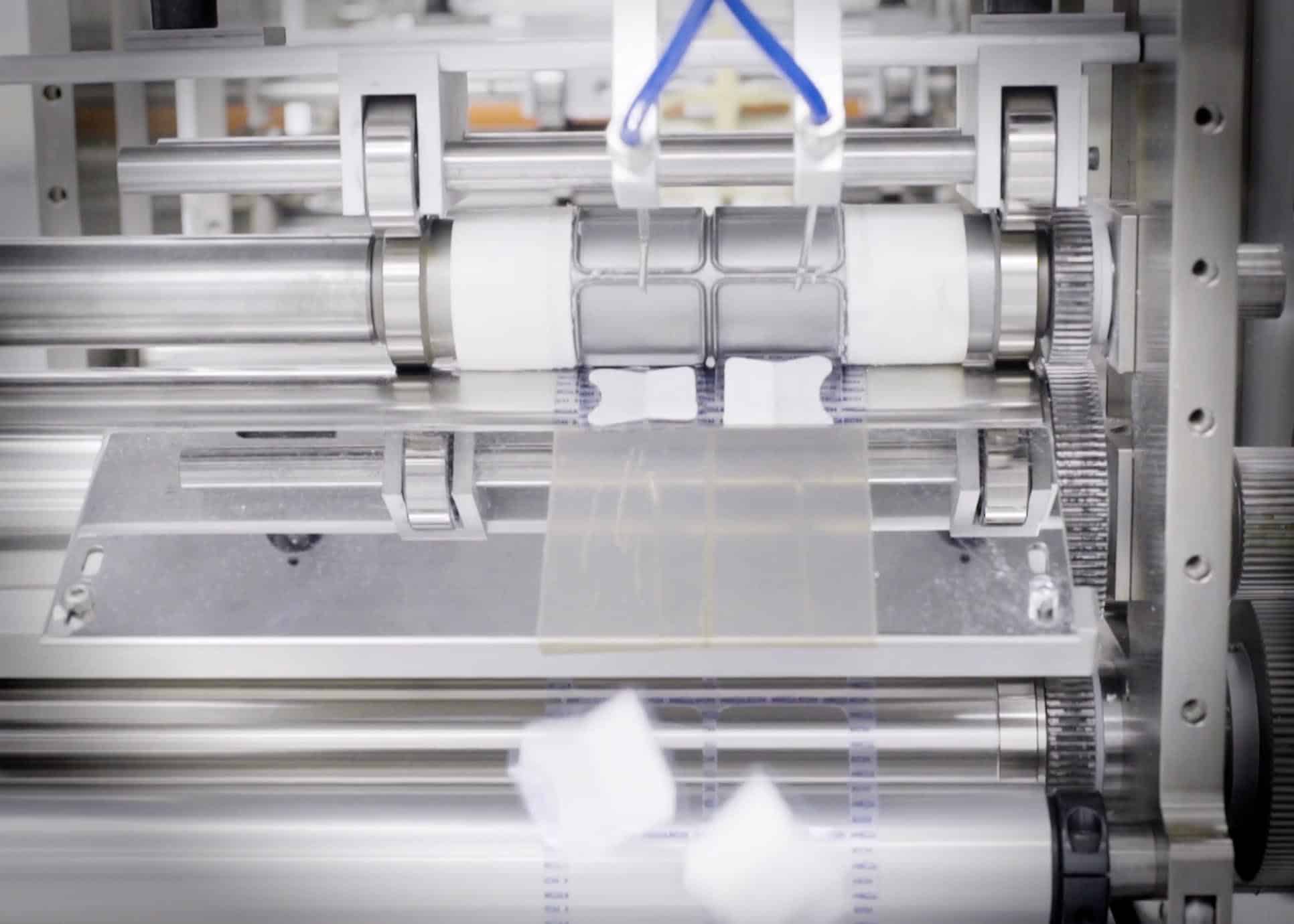

Rotary die cutting is the fastest and most efficient die cutting process.

Hi-Tech has over 30 rotary die cutting presses, 12 in certified cleanrooms. Including 8 state of the art, servo presses with up to 14 stations, capable of handling widths up to 24” wide. Servo presses in certified cleanrooms are capable of island placement with electronic registration and inline heat seal pouching.

- Electronic Registration and Island Placement – Pre-cut shapes of adhesive are laminated to material during the die cutting process, leaving adhesive positioned only in the specified area(s). Adhesive free substrates can also be island placed.

- Minimal to no scrap

- Tight tolerance island placement

- In-line Pouching

- Heat seal pouching creates a moisture vapor barrier

- Cold seal pouching is the fastest, lowest cost in-line pouching option

- Up to 24” wide

- In-line flexographic printing, uv, and heat cure

- Servo Rotary Die Cutting Services in Certified Cleanrooms

- Multi-layer Laminations & in-line island placement with up to 14 stations

- Register and die cut pre-printed materials utilizing electronic registration

- Custom Built, one-of-a-kind rotary presses